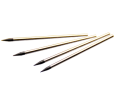

Plastic ejecting needles

Mainly applied to LED chip sorting machine and semiconductor IC die bonding for assembly process.

Standard:

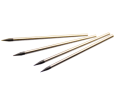

Length: 8 mm, Diameter: 0.7 mm, Taping angle: 15 degree, Tip radius: 100 um

Standard:

Length: 12 mm, Diameter: 0.7 mm, Taping angle: 20 degree, Tip radius: 50 um

Standard:

Length: 17 mm, Diameter: 0.7 mm, Taping angle: 20 degree, Tip radius: 150 um

More information

Product Information

• Applications:

- Plastic ejecting needles are designed and made by two sections with different materials.

- The body in diameter of 0.7 mm is made of stainless steel to strengthen structure stability and a plastic needle is mounted on top of the body to replace conventional tungsten carbide, in which the purpose is to take the advantage of plastic material to prevent the damage of pinning and needle mark on the chip bottom side.

- The plastic ejecting needles are specifically produced by G.C Micro and have been qualified by many companies.

- G.C Micro is able to provide variant kinds of plastic ejecting needles based on the requested spec of tip radius and structure design depending on variant die dimension and aspect ratio.

• Main specifications:

| Main specifications | ||

| Parameter | Specifications | Remark |

| Diameter | 0.7 mm (+/- 0.05 mm) | Standard |

| Length | 12~17 mm (+/- 0.05 mm) | Custom design available |

| Taping angle | 15~20 degree (+/- 1 degree) | Custom design available |

| Tip radius R | 30~300 um | Custom design available |

| Material | Stainless steel + high-hard plastic material | |

| Hardness | > M108/R121 | Rockwell Rockwell hardness |

※The data was measured by G.C Micro with our calibrated machine and it still has to be correlated with customers after qualification.

※All materials are compliant with SGS RoHS testings.

Product specifications

■ Plastic ejecting needles:

| Product specifications | |||||

| Part number | Length (mm) | Diameter (mm) | Taping angle (degree) | Tip radius (um) | Remark |

| A-IEB0070017AF | 17 | 0.7 | 0 | 700 | flat |

| A-IEB1503017A | 17 | 0.7 | 15 | 30 | |

| A-IEB1505017A | 17 | 0.7 | 15 | 50 | |

| A-IEB1507517A | 17 | 0.7 | 15 | 75 | |

| A-IEB1510017A | 17 | 0.7 | 15 | 100 | |

| A-IEB1510008A | 8 | 0.7 | 15 | 100 | |

| A-IEB1515017A | 17 | 0.7 | 15 | 150 | |

| A-IEB2005017A | 17 | 0.7 | 20 | 50 | |

| A-IEB2005012A | 12 | 0.7 | 20 | 50 | |

| A-IEB2007517A | 17 | 0.7 | 20 | 75 | |

| A-IEB2010017A | 17 | 0.7 | 20 | 100 | |

| A-IEB2012517A | 17 | 0.7 | 20 | 125 | |

| A-IEB2015017A | 17 | 0.7 | 20 | 150 | |

| A-IEB2020017A | 17 | 0.7 | 20 | 200 | |

| A-IEB2030017A | 17 | 0.7 | 20 | 300 | |

| A-IEZ00C0017AF | 17 | 1.2 | 0 | 1200 | flat |

| A-IEB1520012A | 12 | 0.7 | 15 | 200 | |

| A-IEB2005021A | 21 | 0.7 | 20 | 50 | |

| A-IEB2007512A | 12 | 0.7 | 20 | 75 | |

| A-IEB2010012A | 12 | 0.7 | 20 | 100 | |

| A-IEB2015012A | 12 | 0.7 | 20 | 150 | |

Spec sheet download:

• Please contact us via email of service@gcmicro.com.tw or dial +886-3-464-2535 directly to obtain password for spec sheet PDF file and/or having any custom specified specifications.