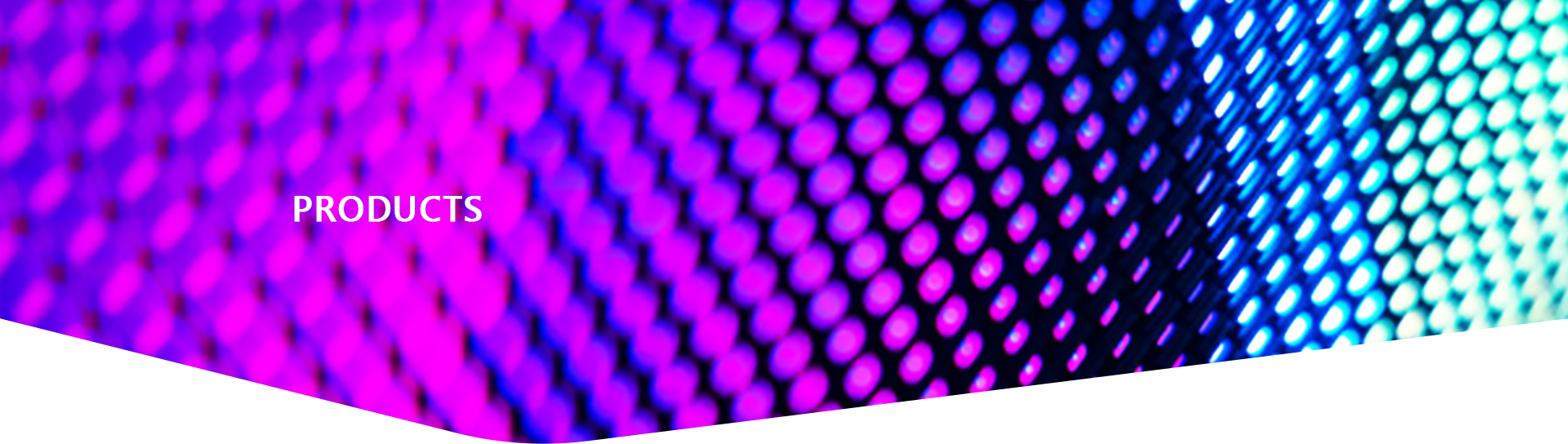

BeCu Probes

Mainly applied to probing machine for chip testing by electrically contact to LED bonding pads and apply current/voltage to obtain output characteristics.

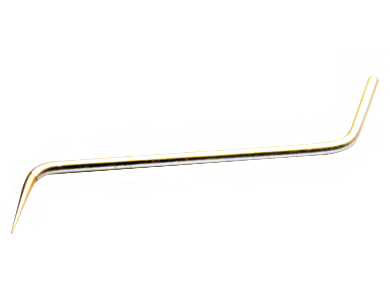

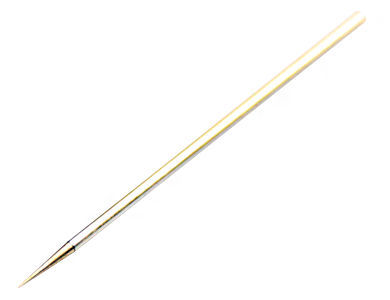

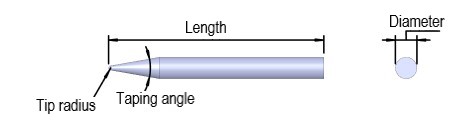

Straight type:

Length: 19 mm, Diameter: 0.5 mm, Taping angle: 10 degrees, Tip radius: 6 um

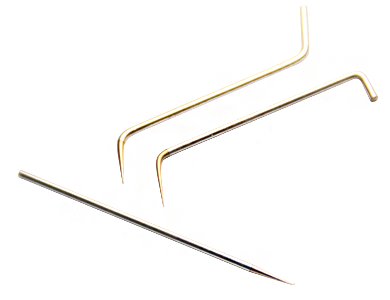

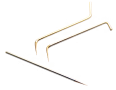

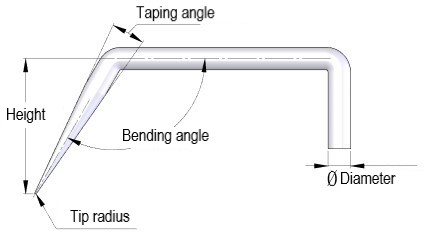

Bending type:

Length: 19 mm, Diameter: 0.5 mm, Bending angle: 120 degrees,Taping angle: 10 degrees, Tip radius: 6 um

More information

Lightening G.C Micro Technology and remain consistently

BeCu contact probes have been utilized in the LED chip testing process for a long while as its highly reliable performance. We G.C Micro have our own splendid production experience on BeCu probes with consolidated quality control and price competitiveness.

During the past years, our BeCu probes have been used and qualified by many worldwide international companies where we always believe in the value of G.C Micro Technology and keep it in high grade level to strengthen ourselves and remain competitive consistently.

Product Information

- Suitable in the probe testing LED chips for obtaining opto-electronic output characteristics;

- Suitable in the probe testing VCSEL, EELD, DFB chips for obtaining opto-electronic output characteristics.

- Suitable in the probe testing photo-sensitive devices such as Photodiode (PD), Phototransistor (PTR), Schottky diode and Zener diode for obtaining opto-electronic output characteristics.

| Main specifications | ||

| Parameter (Parameter) | Specifications | Remark |

| Diameter | 0.5 mm (+/- 0.05 mm) | Standard |

| Length | 19.0 mm (+/- 0.05 mm) | Custom design available |

| Taping angle | 6~13 degree | Custom design available |

| Tip radius R | 2~100 um | Custom design available |

| Bending degree | 90~130 degree | Custom design available |

| Material | Be/Cu alloy with Ag coated | Be~1.82%, Cu~97% |

| Hardness | >300 Hv | Vickers hardness |

※The data was measured by G.C Micro with our calibrated machine and it still has to be correlated with customers after qualification.

※All materials are compliant with SGS RoHS testings.

Product specifications

■ Straight type

| Product specifications | |||||

| Part number | Length (mm) | Diameter (mm) | Taping angle (degree) | Tip radius (um) | Remark |

| A-BEA0800719A | 19 | 0.5 | 8 | 7 | |

| A-BEA1000231A | 31.75 | 0.5 | 10 | 2.5 | |

| A-BEA1000219A | 19 | 0.5 | 10 | 2 | |

| A-BEA1000419A | 19 | 0.5 | 10 | 4 | |

| A-BEA1000619A | 19 | 0.5 | 10 | 6 | |

| A-BEA1000616A | 16 | 0.5 | 10 | 6 | |

| A-BEA1002019A | 19 | 0.5 | 10 | 20 | |

| A-BEA0600519A | 19 | 0.5 | 6 | 5 | |

| A-BEA0700219A | 19 | 0.5 | 7 | 2 | |

| A-BEA1200619A | 19 | 0.5 | 12 | 6 | |

| A-BEA1201019A | 19 | 0.5 | 12 | 10 | |

| A-BEA1000615A | 15 | 0.5 | 10 | 6 | |

| A-BEA1003032A | 32 | 0.5 | 10 | 30 | |

| A-BEA1501530A | 30 | 0.5 | 15 | 15 | |

| A-BEA1502030A | 30 | 0.5 | 15 | 20 | |

| A-BEA1503030A | 30 | 0.5 | 15 | 30 | |

| A-BEA1504030A | 30 | 0.5 | 15 | 40 | |

| A-BEA1505030A | 30 | 0.5 | 15 | 50 | |

■ Bending type

| 產品規格 | |||||||

| Part number | Length (mm) | Diameter (mm) | Bending angle (degree) | Taping angle (degree) | Tip radius | Height (mm) | Remark |

| A-BMA06005A4045A | 20 | 0.5 | 120 | 6 | 5 | 4.0~4.5 | |

| A-BMA07002C3035AA | 19 | 0.5 | 105 | 7 | 25 | 3.0~3.5 | Tip roughening |

| A-BMA07002E3035AA | 19 | 0.5 | 125 | 7 | 2.5 | 3.0~3.5 | Tip roughening |

| A-BMA07005D4045A | 19 | 0.5 | 112 | 7 | 5 | 4.0~4.5 | |

| A-BMA07006A3032AB | 19 | 0.5 | 120 | 7 | 6 | 3.0~3.2 | Tip Atomization |

| A-BMA07006A3035A | 19 | 0.5 | 120 | 7 | 6 | 3.0~3.5 | |

| A-BMA07006E3035AA | 19 | 0.5 | 125 | 7 | 6 | 3.0~3.5 | Tip roughening |

| A-BMA07012E3035AA | 19 | 0.5 | 125 | 7 | 12 | 3.0~3.5 | Tip roughening |

| A-BMA08001B3032A | 19 | 0.5 | 110 | 8 | 1 | 3.0~3.2 | |

| A-BMA08003B3032AG | 19 | 0.5 | 110 | 8 | 3 | 3.0~3.2 | Tip brightening |

| A-BMA08003B3033AG | 19 | 0.5 | 110 | 8 | 3 | 3.0~3.3 | Tip brightening |

| A-BMA08006D4244A | 19 | 0.5 | 112 | 8 | 6 | 4.2~4.4 | |

| A-BMA08006D6070A | 22 | 0.5 | 112 | 8 | 6 | 6.0~7.0 | |

| A-BMA08010D4244A | 19 | 0.5 | 112 | 8 | 10 | 4.2~4.4 | |

| A-BMA08025D4244A | 19 | 0.5 | 112 | 8 | 25 | 4.2~4.4 | |

| A-BMA08050D4244A | 19 | 0.5 | 112 | 8 | 50 | 4.2~4.4 | |

| A-BMA08100D4244A | 19 | 0.5 | 112 | 8 | 100 | 4.2~4.4 | |

| A-BMA08200D4244A | 19 | 0.5 | 112 | 8 | 200 | 4.2~4.4 | |

| A-BMA09003B3032A | 19 | 0.5 | 110 | 9 | 3 | 3.0~3.2 | |

| A-BMA09003B3033A | 19 | 0.5 | 110 | 9 | 3 | 3.0~3.3 | |

| A-BMA10001A3032A | 19 | 0.5 | 120 | 10 | 1 | 3.0~3.2 | |

| A-BMA10002A3032A | 19 | 0.5 | 120 | 10 | 2.5 | 3.0~3.2 | |

| A-BMA10003A3032B | 19 | 0.5 | 120 | 10 | 3 | 3.0~3.2 | |

| A-BMA10003A3032C | 19 | 0.5 | 120 | 10 | 3 | 3.0~3.2 | |

| A-BMA10003B3032A | 19 | 0.5 | 110 | 10 | 3 | 3.0~3.2 | |

| A-BMA10012B3032A | 19 | 0.5 | 110 | 10 | 12 | 3.0~3.2 | |

| A-BMA10013A3235A | 19 | 0.5 | 120 | 10 | 13 | 3.2~3.5 | |

| A-BMA10016A3032A | 19 | 0.5 | 120 | 10 | 16 | 3.0~3.2 | |

| A-BMA10019A3032A | 19 | 0.5 | 120 | 10 | 19 | 3.0~3.2 | |

| A-BMA10050F3035A | 46.2 | 0.5 | 140 | 10 | 50 | 3.0~3.5 | |

| A-BMA10100A3032A | 19 | 0.5 | 120 | 10 | 100 | 3.0~3.2 | |

| A-BMA13006B3034A | 19 | 0.5 | 110 | 13 | 6 | 3.0~3.4 | |

| A-BMA13007A3032A | 19 | 0.5 | 120 | 13 | 7 | 3.0~3.2 | |

| A-BMA10012B3032A | 19 | 0.5 | 110 | 10 | 12 | 3.0~3.2 | |

| A-BMA10013A3235A | 19 | 0.5 | 120 | 10 | 13 | 3.2~3.5 | |